Krasimira Dimitrova

ORCID iD: 0000-0001-8533-156X

Technical University of Varna, Bulgaria

https://doi.org/10.53656/igc-2024.04

Pages 98-111

Abstract. The scientific and technical development, which is characterized by increasingly dynamic rates, made it possible to harness all components of the biosphere in material production. The industrial revolution ushered in the linear economy. Raw materials and materials are used for goods that are discarded after use. The trend of excessive consumerism gives rise to serious environmental, economic, cultural, political and social problems, leads to depletion of natural resources and ecological imbalance. The traditional linear economy is based on the extraction of natural resources to produce products that end their life cycle as waste. The linear economy is still deeply rooted. In the modern reality the „take-make-consume-throw“ model must remain irreversibly in the past and be transformed into a higher degree of responsible business development, where waste is transformed into raw materials requiring responsible thinking and behaviour for sustainable management and growth. This publication presents the first stage of a scientific study of the possibilities of efficient use of natural resources, increasing the use of secondary raw materials, securing access to strategic resources and reducing the dependence on imports in the EU in the process of transition to a circular economy. A comprehensive analysis of the material resources used in the EU economy was made. This analysis will serve as a basis for further research into the possibilities for a higher degree of responsible business development, where waste is transformed into raw materials requiring responsible thinking and behaviour for sustainable management and growth.

Keywords: linear economy; circular economy; resources; recycling; critical raw materials; material outputs; waste

JEL: O32, O44, O52

1. Introduction

Every historical time has its fateful problems. Today’s ones have a specific feature – they are global and directly affect all humanity, all civilization. Perhaps the greatest problem of humanity is the problem related to its survival and that is the ecological problem. This problem is a real consequence of the interaction between society and nature. It is an expression of the contradictory nature of this interaction, an object of scientific analysis and research, an indicator of urgent practical decisions, caused by today’s unfavourable interdependence between the material production activity of man and his living environment, between needs and objective possibilities for their satisfaction. A number of scientific and technical achievements are turning into weapons for the destruction of life, of nature, which means in practice an ecological catastrophe, an irreversible disruption of the ecological balance on a global scale, or in other words, death for all living things on the planet.

The main objective set in this scientific research is to analyze the possibilities for efficient use of natural resources, increasing the use of secondary raw materials, ensuring access to strategic resources and reducing dependence on imports.

Main tasks to achieve the set objective:

- To determine the benefits of the transition to a circular economy;

- To make a comprehensive analysis of the material resources used in the EU economy;

- To explore the possibilities for a higher degree of responsible business development, where waste is transformed into raw materials, requiring responsible thinking and behavior for sustainable management and growth.

Subject of research: The use of raw materials and the generation of less waste in circular conditions.

The object of research is the economy of the EU.

The functioning of any economic system can be represented by the mathematical logic „Input

– Transformation – Output“ (Fig. 1)

Figure 1. Functioning of any economic system under mathematical logic “Input – Transformation – Output”

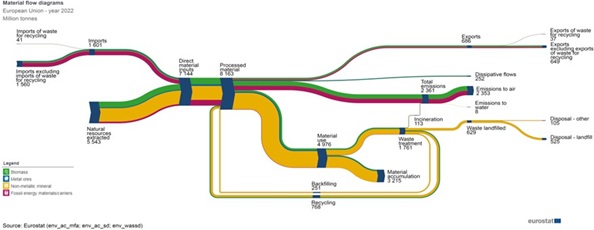

There is no waste in nature and nothing is lost or wasted. In a linear economy, processes start from extracting resources from nature. Most of these mining processes are associated with the generation of noise, vibration, greenhouse gases (carbon dioxide, methane, nitrogen oxides), sulfur oxides, ozone, etc., fine dust particles, solid, toxic, hazardous waste, etc., which endangers the health and quality of life of workers and has a detrimental effect on nature. In this linear model, raw materials are used, products are created from them, products are consumed, and waste is disposed of. This model relies on large quantities of cheap and accessible materials and energy sources. The concept of a circular economy is built in opposition to the linear model of the economy. The use of raw materials and materials that can be recycled many times and the production of products that can be repaired leads to the generation of less waste and is at the heart of the circular economy (Karev & Dobrev, 2019). This requires the development of activities for the separate collection, recycling and recovery of waste from the consumption of products in order to close the circle. Waste contains valuable raw materials that could be used in the production of new products and reduce the EU’s dependence on third countries for the import of critical raw materials. The European Union (EU) imports more than 50% of its raw materials. In the circular economy, the models of natural cycles are followed, and the aim is to reduce the loss of energy and materials during production, as well as the generation of landfilled waste during consumption (ESCRB, 2019). The idea of the circular economy can be visualized through the material flow diagram. (Fig. 2).

Figure 2. Diagram of material flows in the EU (Eurostat, 2024)

- Benefits of the transition to a circular economy

– Environmental protection – reusing and recycling products reduces the need to extract natural resources and limits the associated damage to ecosystems that threat biodiversity. The circular economy also contributes to reducing greenhouse gas emissions. According to data from the European Environment Agency, 9.1% of greenhouse gas emissions in the EU are related to industrial processes and product use, and 3.3% of emissions are related to waste management. Designing more efficient and more sustainable products would help limit the consumption of energy and other resources. Switching to reliable products that can be reused, improved and repaired would lead to less waste. Packaging is becoming more and more of a global problem. The improvement of packaging design should be linked to the promotion of reuse and recycling. Production that uses fewer resources (energy, water, land and materials) would have a positive impact on climate, marine litter and biodiversity through:

– Increasing resource productivity by 30% by 2030 would increase GDP by 0.8% and create two million new jobs in the EU.

– Energy and cost savings associated with increased resource efficiency.

– The use of secondary raw materials instead of primary raw materials in the production of metal, glass and paper leads to energy savings of 20% to 90%, as well as significant water savings.

– Reducing dependence on raw materials – The world’s population is growing, and with it the demand for raw materials. However, the extraction of raw materials faces natural limitations. Many of the countries in EU do not have a sufficient amount of raw materials. Eurostat data show that the EU imports about 50% of the raw materials it consumes. The supply of raw materials involves risks, such as price volatility, availability and dependence on imports. Recycling raw materials reduces the risks associated with their procurement – the EU becomes less dependent on global crises, price changes and geopolitical pressures. This is particularly true for key raw materials needed to develop technologies to meet climate goals, such as batteries and electric motors.

- Material resources, used in EU economy

А. Materials invested in durable stocks

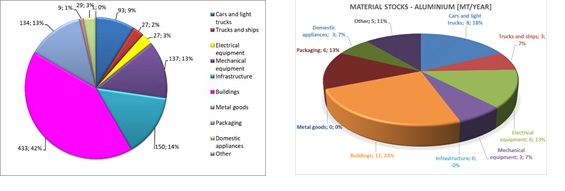

Material stocks: products and infrastructure that are typically used for more than one year. This includes roads, means of transport (boats, planes, trains, heavy goods vehicles and cars), buildings, furniture and other consumer goods. Materials can remain in storage for decades. Each year, materials added to stockpiles are about twice as high as materials removed from stockpiles as a result, inventories grow. According to data from Allwood and Cullen’s research (Allwood & Cullen, 2011, pp. 30-33), the most widely used in the EU are steel and aluminium. In Fig. 3 shows the quantitative consumption and distribution of steel and of aluminium and aluminium alloys by industry structure.

Figure 3. Material stocks from Steel and Aluminum in million tons per year in EU (Author).

The EU is particularly exposed to risks related to the supply of 34 critical raw materials identified by the European Commission. Many of these raw materials are essential for high- tech products. Some sectors are of particular strategic importance to the EU’s renewable energy, digital technologies, space and defence objectives. Other applications of critical raw materials (European Council, 2024): Tungsten – in vibrating technology in telephones; Lithium, Cobalt and Nickel – in electric vehicles; Boron – wind turbines; Silicon metal – semiconductors; Borates – in manufacture of glass and production of fertilisers for plant growth; Magnesium and Scandium – building and flying aeroplanes. From the 34 critical raw materials (CRM) identified, a special list of 17 strategic raw materials has been created, referring to materials whose importance is expected to grow exponentially in terms of supply, for which there are complex production requirements and are therefore exposed at greater risk of supply problems. Fig. 4 shows 34 critical raw materials, 17 of which are considered as strategic raw materials (in yellow) (European Council, 2024).

Figure 4. Critical raw materials, 17 of which are considered as strategic raw materials Source: European Council (2024)

Table 1 shows the main EU suppliers of critical raw materials (according to Eurostat data) (European Council, 2024).

Table 1. Main suppliers of critical raw materials to EU

| China | |||||

| LREEs – light rare earth | HREEs – heavy rare earth | ||||

| Baryte | 45%, | Cerium | 85%, | Dysprosium | 100%, |

| Bismuth | 65% | Lanthanum | 85%, | Erbium | 100%, |

| Gallium | 71%, | Neodymium | 85%, | Europium | 100%, |

| Germanium | 45%, | Praseodymium | 85%, | Gadolinium | 100%, |

| Magnesium | 97% | Samarium | 85% | Holmium | 100%, |

| Natural graphite | 40%, | Lutetium | 100%, | ||

| Scandium | 67%, | Terbium | 100%, | ||

| Tungsten | 32%, | Thulium | 100%, | ||

| Vanadium | 62% | Yttrium | 100% | ||

| Türkiye | Kazakhstannnnn | Poland | |||

| Antimony | 63%, | Phosphorus | 65%, | Coking coal | 26%, |

| Boron | 99%, | Titanium metal | 36% | Copper | 19% |

| Feldspar | 51% | ||||

| Russia | Finland | Norway | |||

| Nickel | 29% | Nickel | 38% | Silicon metal | 33% |

| Belgium | France | Spain | |||

| Arsenic | 59% | Hafnium | 76% | Strontium | 99% |

| Guinea | Congo, D.R. | Morocco | |||

| Aluminium | 63% | Tantalum | 35% | Phosphate rock | 27% |

| South Africa | Qatar | Australia | |||

| Manganese | 41% | Helium | 35% | Coking coal | 25% |

| Brazil | Chile | Mexico | |||

| Niobium | 92% | Lithium | 79% | Fluorspar | 33% |

| USA | |||||

| Beryllium | 60% | ||||

From the above information, it is visible that CRMs are mostly sourced outside the EU. Currently, for certain critical raw materials, the EU is solely dependent on one country: China provides 100% of the EU’s supply of heavy rare earth elements; Turkey provides 98% of the EU’s supply of boron; South Africa provides 71% of the EU’s needs for platinum. To reduce dependence on third countries to access critical raw materials, EU set the following objectives for 2030: at least 10% of the EU’s annual consumption from EU extraction; at least 40% of the EU’s annual consumption from EU processing; at least 25% of the EU’s annual consumption from domestic recycling; no more than 65% of the Union’s annual consumption of each strategic raw material at any relevant stage of processing from a single third country.

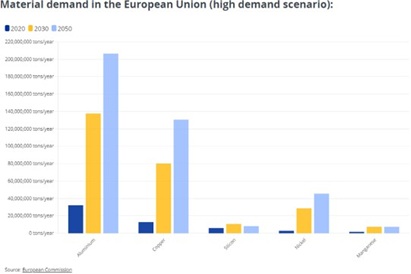

The EU’s objective to cut greenhouse gas emissions by at least 55% by 2030 sets Europe on a responsible path to becoming climate neutral by 2050. This requires delivering the twin transition, decarbonising the energy system and ensuring autonomy through access and transformation of critical raw materials. Fig. 5 shows Material demand in the EU of the five CRMs with the highest demand in the EU in 2020 and the estimated needs of these five CRMs for 2030 and 2050 (European Council, 2024). Aluminium plays a critical role in Europe’s transition to a sustainable future, as it is a key component in almost all of the clean energy technologies prioritized in the Net Zero Industry Act, including solar PV systems, wind turbines, grid technologies, and batteries. It is expected that its use to increase by 543% from 2020 to 2050. The data represents a CRM demand forecast for five strategic EU sectors: renewable energy, electric mobility, industry, information and communication technology and space and defence.

Figure 5. The five CRMs with the highest demand in the EU Source: European Council (2024)

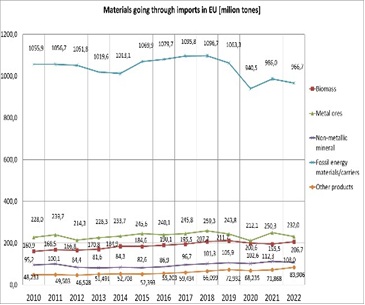

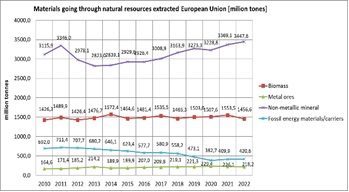

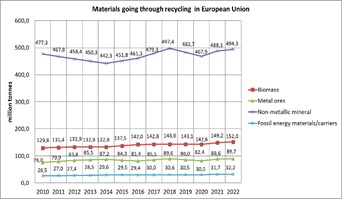

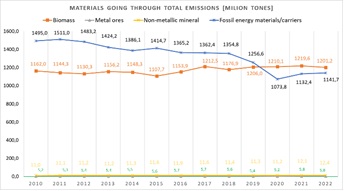

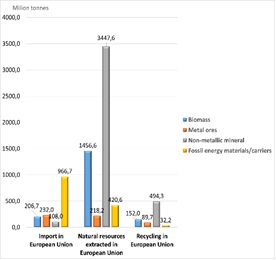

Fig. 6, 7 and 8 show diagrams of the consumption of various resources in EU for the period 2010÷2022, with the data taken from Eurostat (2024).

Figure 6. Materials going through import in EU for the period 2010 ÷2022 (Author)

Figure 7. Materials going through natural resources extracted in EU for the period 2010 ÷2022 (Author)

Figure 8. Materials going through recycling in EU for the period 2010 ÷2022 (Author)

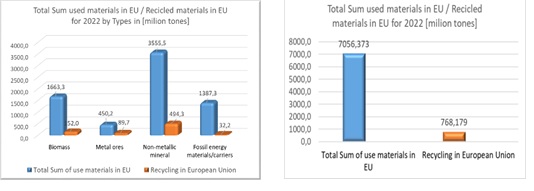

According to a study measuring the progress towards a circular economy conducted by a team of Willy Haas (Mayer et al., 2018), it is found that for the year 2014, 7.4 Gt of materials are processed in the EU and only 0.71 Gt of them were from recycled materials. In the present study, applying a similar framework of monitoring indicators, it was found that for 2022 the ratio remained almost unchanged. (Fig. 9 ÷ Fig. 11)

Figure 9. Grouping the materials used in EU in year 2022 by sources of delivery (Author)

Figure 10. Total amount of materials used in EU for year 2022, compared with the total amount of recycled materials by types (Author)

Figure 11. Materials going through total emission for the period of 2010 ÷ 2022 (Author)

The main challenge is related to the growing stockpiles of materials: Stockpiles of materials are growing at a high rate with net additions of 2.6 Gt/year (35% of processed materials). Stockpiles are expected to continue to grow in the coming decades, and global use of material resources is expected to double between 2010 and 2030. Along with this, the amounts of all waste and emissions leaving the economy are also increasing. This includes CO2 emissions and waste deposited on land (EPRS, 2024). While the transition to a circular economy can provide a number of opportunities, the road ahead is fraught with obstacles. The scope of the circular economy extends far beyond waste prevention and management. It is about efficient use of natural resources, increasing the use of secondary raw materials, ensuring access to strategic resources and reducing dependence on imports. At stake is Europe’s footprint on the environment, the competitiveness of the European economy and ultimately the standard of living of EU citizens. In addition, competition and competitiveness must shift their focus as the most important social and economic systems become increasingly digitally networked (Sterev & Milusheva, 2024). The logistics approach to managing material flows requires the integration of separate sections of the logistics process into a single system capable of quickly and economically providing the necessary materials, raw materials, semi-finished products and finished products at the right place in a certain time (Antonov, 2016). Effective use of resources is key to strengthening the competitiveness of the economy, creating conditions for growth and creating new jobs. According to forecasts, the transition to a circular economy could create 700,000 jobs in the EU by 2030. All this requires the socially responsible attitude towards the environment and society, as well as the modelling of key competences for sustainable development (Dragozova & Kovacheva, 2023).

4. Conclusion

Designing products and materials in a way that allows multiple use and recycling will stimulate innovation in various sectors of the economy. Consumers will also gain access to more sustainable and economical products, which will save those costs in the long run and improve their quality of life. Research and development in this area can also focus on product eco-design and the sharing economy, where the economy is focused on the use of the product (ie the rental, leasing or subscription model) rather than ownership. The modern design of industrial enterprises requires even at its earliest stage, i.e. in the course of the development of the concepts of the industrial enterprise, to determine the logistical goals related to the purchase of raw materials and materials, production, placement, and also with the utilization of waste (Panayotova & Makedonska, 2010). This scientific research has an analytical character and marks the beginning of a more in-depth research work, jointly with two doctoral students. The development of working sustainable models of production and consumption, reducing the material intensity of enterprises and preventing the formation of waste in accordance with the principles of the circular economy concept will be set in future research projects.

REFERENCES

Allwood, J. & Cullen, J. (2011). Sustainable materials – With Both Eyes Open. UIT Cambridge.

Antonov, A. (2016). Transportna logistichna systema za ekologichen morfologichen analiz na otpadaci. University Press “Episkop Konstantin Preslavski”.

Dragozova, E. & Kovacheva, S. (2023). Research on the Sustainable Development Competences of the Landscape Architect in Practice. Strategies for Policy in Science and Education, 31(6s), pp 56 – 67. https://doi.org/10.53656/str2023- 6s-5-res

Economic and Social Council of the Republic of Bulgaria (ESCRB). (2019). The Circular Economy – Characteristics and Opportunities for Development. (2019).

European Council. (2024). An EU Critical Raw Materials Act for the Future of EU Supply Chains. https://www.consilium.europa.eu/en/infographics/critical-raw-materials/

European Parliamentary Research Service (EPRS). (2024). Infographics. Think Tank. https://www.europarl.europa.eu/thinktank/en/infographics

Eurostat. (2024). Material Flow Diagram. Eurostat. https://ec.europa.eu/eurostat/cache/sankey/circular_economy/sankey.html?geos=EU27&year= 2022&unit=THS_T&materials=TOTAL&highlight=&nodeDisagg=0101100100&flowDisagg=true&language=EN&material=TOTAL

Mayer, A., Haas, W., Wiedenhofer, D., Krausmann, F., Nuss, P. & Blengini, G. A. (2018). Measuring Progress towards a Circular Economy: A Monitoring Framework for Economy wide Material Loop Closing in the EU28. Journal of Industrial Ecology, 23(1), 62 – 76. https://doi.org/10.1111/jiec.12809

Karev, N. & Dobrev R. (2019). Usloviya za ikonomicheska zhiznesposobnost na retsikliraneto. In Mezhdunarodna nauchna konferentsiya „Sŭvremenni paradigmi v upravlenieto v konteksta na neprekŭsnatata promyana: Sbornik s dokladi (pp. 307 – 312). Academic Publishing, Ltd.

Panayotova, Т. & Makedonska, D. (2010). Elaboration of Logistic Concept in Projection of Industrial Enterprise. Conference proceedings of VIIIth International Scientific Conference “Management and Engineering”, 126 – 132.

Sterev, N. & Milusheva, V. (2024). Competitiveness of Textile Producers in Digital Business Era. Strategies for Policy in Science and Education, 32(3s), 29 – 41. https://doi.org/10.53656/str2024-3s-3-com