Dimitar Dimitrakiev

ORCID iD: 0000-0002-9960-2372

WoScience ResearcherID: E-3595-2012

Nikola Vaptsarov Naval Academy – Varna, Bulgaria

Dobrin Milev

Nikola Vaptsarov Naval Academy – Varna, Bulgaria

https://doi.org/10.53656/igc-2024.18

Pages 155-161

Abstract. Chemical tankers are much more complicated than ordinary tankers. This type of vessels intends to carry dangerous chemicals as well as flammable and other liquid products. For precaution of safety there’s no difference between general oil tankers and chemical tankers in principle, since they upgrade the risks with toxic, reactivity and other hazards. Regarding the construction the chemical tankers are well equipped – they have more pumps, valves, blanks and lines then ordinary tanker vessel. They may have onboard many different kind of cargo at the same time. These cargoes may be bulk liquid chemicals, solvents, lubricating oils, vegetable and animal oils, petroleum products, and other such liquids. They have to be handled safely. Care is absolutely essential throughout the whole operation. Not all of these cargoes are dangerous, but more of them will have some hazards connected with their properties.

Chemical tankers masters and crew should observe all the international procedures for handling such cargoes, described in the approved manuals and codes. The shipping companies operating such vessel are obliged to develop safety and quality procedures, in order to avoid incidents with chemical products.

Keywords: chemical tankers, maritime transport, safety, cargo handling

JEL: L91

- Introduction

Chemical products may undergo a chemical or physical reaction during handling or carriage on ship tankers in a number of ways. Common reactions are with water or moisture, air, other substances or materials and with itself. Ships’ crew must be conversant with products which are reactive and must ensure that adequate precautions are taken.

Reactive chemicals (CHRIS, 1999) are divided into:

– Unstable or self-reacting chemicals, either polymerizing or decomposing;

– Chemicals which react with water to emit dangerous gases;

– Chemicals capable of reacting with oxygen in the air, either forming peroxides or liable to putrefaction;

– Incompatible chemicals, which react dangerously if mixed together.

- Properties of chemical tankers cargoes

- Self-reactivity and polymerization

Self-reactivity means that the properties of a substance are such that under certain conditions it will undergo a self-reaction under certain conditions. The most commonly known form is polymerization and is usually caused by the product being exposed to heat, or being stored over a long period. In many cases polymerization is a slow and natural process and does not pose a safety hazard.

If the precautions required for handling or carrying such cargoes are not complied with, run-off polymerization may result. There may be an exothermic reaction with a rapid build-up of heat and toxic gases.

Polymerization is exothermic and results in the generation of heat. If left unchecked the result may be over pressurization of the tank. If there is an unexpected increase in cargo temperature an exothermic reaction should be suspected and immediate steps taken to reduce the temperature. Further, as polymerization proceeds it produces heavier and more viscous liquids, or even solids, that may block vents and suctions.

The cargo temperature must be monitored daily in order to detect any unexpected rise as early as possible. If a rise in temperature is observed which cannot be explained normal changes in the air or seawater temperature the office must be immediately and urgently informed.

Substances that are self-reactive are inhibited. The Master or Chief Officer must ensure that an Inhibitor Certificate is provided prior to the carriage of such products (International Chamber of Shipping, 2021). The manufacturer should provide the certificate specifying:

– The name and amount of additive present;

– Whether the additive is Oxygen-dependent;

– The date the additivę was added to the product and thẹ duration of its effectiveness;

– Any temperature limitations qualifying the additive’s effective lifetime;

– The action to be taken should the length of the voyage exceed the effective lifetime of the additive. Note that the inhibitor may added either to the shore tanks prior to loading or to the vessel’s tanks either during or after loading.

- Decomposition

Substances that decompose do so into lighter and more volatile substances. Whilst doing so they generate heat and evolve toxic and flammable gases. The decomposition is often initiated by carriage at too high a temperature, or by contact with small amounts of other chemicals, or impurities acting as catalysts. A catalyst accelerates the reaction without taking part in it. The most common decomposition catalysts are acids, alkalis and metals, and decomposition can be prevented by the addition of a stabilizer.

The main hazards with such reactions are the generation of heat and the production of polymers. Where such cargoes are carried the charterer’s requirements with respect to the carriage temperature of the cargo must be strictly adhered to and the temperature must be carefully monitored (Dimitrakieva et al., 2021b; Atanasova, 2023). If there’s an unexpected increase in cargo temperature an exothermic reaction should be suspected and immediate steps taken to reduce the temperature.

- Reactivity with water

Some products react with water or moisture. Most typical of these are isocyanides and propylene oxide. Such reactions may generate gases which are flammable or toxic, or both, and which pose a danger to the vessel and personnel.

These substances must not be loaded into a cargo tank unless the tank has been thoroughly purged with Nitrogen, and a positive pressure Nitrogen blanket must be maintained throughout carriage.

Such products must also never be heated with water as the heating medium. Adjacent cargo tanks should either be empty or loaded with a compatible cargo. Adjacent ballast tanks must be drained and free from any ballast.

For Propylene Oxide all adjacent spaces should either be loaded with a compatible cargo or be fully inerted.

Other substances that react with water are acids when diluted. Dilution with water may not only evolve toxic gases, but may also make the product extremely corrosive and cause damage the cargo tank and associated fittings.

- Reactivity with air

Some products react with air, either in the liquid or the vapor phase, and may form oxygen compounds whereby the oxygen dissolves in the product to gradually form unstable peroxides. Organic peroxides are thermally unstable and may be liable to exothermic, self-accelerating decomposition.

In another group, mainly natural products, putrefaction can occur if the product is exposed to oxygen, usually by the action of bacteria. When a cargo has suffered putrefaction foul odors are evolved which can ultimately be toxic. Carbon monoxide can be produced. However, the min hazard is that the oxygen in the compartment will no longer be sufficient to support life and death when entering such compartments can be virtually instant.

Some of these reactions will pose a danger to the vessel, others simply cause a deterioration in the quality of the product. The key to the prevention of such reactions is the exclusion of air and the control of temperature. Therefore, all such substances are carried either padded or inerted, although some are inhibited to stabilize them.

- Reactivity with other products

Many substances are subject to a dangerous reaction if they come in contact with each other. Such substances are called incompatible substances.

Such reactions can be hazardous, and include the generation of toxic gases, heating of the liquids with subsequent overflow or rupture of the tanks. There may also be the possibility in extreme cases of fire and explosion.

Care should be taken that residues of substances or mixtures containing substances which react in hazardous manner with other substances are segregated from products which they will react with. This includes not only cargo tanks and lines, but also in savealls and residue and slop tanks.

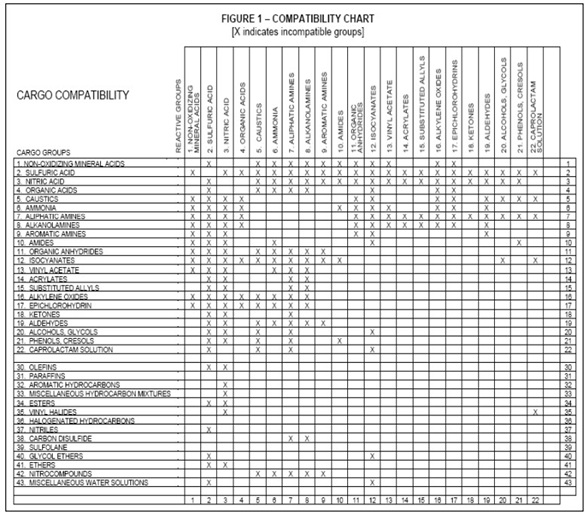

Compatibility charts must be consulted to determine whether substances are compatible or incompatible (Figure 1.)

Figure 1. Compatibility chart on chemical tanker Source: 46 CFR 150 Coast Guard, Department of Homeland Security

- Reactivity with other materials

Some substances react with materials used in the construction of cargo handling equipment (Koritarov, 2021b). All materials used in the cargo handling systems must therefore be of a compatible material.

Care must be taken that no incompatible material is introduced during maintenance, repair or renewal of equipment.

- List of chemical products data onboard tankers

Together with the stowage plan submitted to shipping company operations department for advice (Sterev, 2023), the Master shall produce a „List of Product Data“ specifying:

– Name of Product (Commercial names are not acceptable i.e. it must be possible to identify the product in the Certificate of Fitness and P&A Manual – procedures and arrangements);

– Category I, II or III – according to IBC[1];

– Category X, Y, Z or OS – according to MARPOL Annex II;

– Density;

– Flashpoint;

– Loading, carrying and discharge temperature;

– Melting point;

– Viscosity at 20 degrees centigrade;

– Vapor pressure at 20 degrees centigrade;

– Miscibility with water;

– Lower explosion limit;

– Reactivity with other substances;

– TLV (Treshold Limit Value);

– Cleaning procedures according to the P&A Manual.

- Conclusions

The chemical tanker operation particularities and especially the preparation for dangerous cargo loading and transportation require the application of a number of international maritime conventions, codes and guidelines (Koritarov, 2021a). Furthermore, each cargo is specific, having in mind its chemical composition and physical characteristics, that have to be considered when accepted onboard for stowage and carriage (Dimitrakieva et al., 2021a; Narleva & Gancheva, 2023). A number of indicators have to be monitored during this process and they must remain constant, because otherwise undesired chemical reactions can occur. This fact will lead to unsafe vessel condition, which will threaten crew life, marine environment and ships equipment.

[1] IBC-Code International for the Construction and Equipment of Ships Carrying Dangerous Chemicals in Bulk. (2020). International Maritime Organization

REFERENCES

Atanasova, C. (2023). Transforming Maritime Education for A Digital Industry. Strategies for Policy in Science and Education, 31(6s), 9 – 18. https://doi.org/10.53656/str2023-6s-1-mar

Chemical Hazards Response Information System (CHRIS). (1999). GovInfo. https://www.govinfo.gov/app/details/GOVPUB-TD-PURL-LPS28226

Dimitrakieva, S., Kostadinov, O. & Atanasova, K. (2021a). Comparative Analysis of the Contracts for Maritime Transport Services: Chain of Charter Parties. Pedagogika-Pedagogy, 93(6s), 51 – 62. https://doi.org/10.53656/ped21-6s.04com

Dimitrakieva, S., Kostadinov, O. & Atanasova, K. (2021b). Multilevel Demand for Sea Transportation: Correlation between Baltic Dry Index (BDI) and Coaster Shipping Prices for Sea Routes between Baltic Seaports and Mediterranean Seaports. Pedagogika-Pedagogy, 93(7s), 141 – 148. https://doi.org/10.53656/ped21-7s.12corr

Electronic Code of Federal Regulations (e-CFR): 46 CFR 150 Coast Guard, Department of Homeland Security. Legal Information Institute. https://www.law.cornell.edu/cfr/text/46/chapter-I

International Chamber of Shipping (2022). Bridge procedure guide. (6th Ed.). ICS.

International Chamber of Shipping. (2021). Tanker Safety Guide (Chemicals). (5th Ed.). ICS.

Koritarov, T. (2021a). Application of virtual online techniques in maritime education in a pandemic – new pedagogical environment and issues. In International Scientific Conference Innovative Education for Emerging Maritime Issues (pp. 63-69). Nikola Vaptsarov Naval Academy

Koritarov, T. (2021b). Approaches to the Application of Unmanned Aerial Systems in the Field of Maritime Industry and Education. Notices of the Union of scientists – Varna, 26 – 32. https://www.su-varna.org/izdanij/2021/2021_Proceedings_Morski-nauki_final.pdf

Narleva, K. & Gancheva, Y. (2023). The Role of Maritime Education in Digitalization. Pedagogika-Pedagogy, 95(6s), 132 – 141. https://doi.org/10.53656/ped2023-6s.12

MARPOL Consolidated edition. Annex II. (2022). International Maritime Organization.

Sterev, N. (2023). Pre-Incubation Toolkits for Academic Entrepreneurship Fostering: Bulgarian Case. Strategies for Policy in Science and Education, 31(3s), 90 – 103. https://doi.org/10.53656/str2023-3s